3M™ Scotch-Weld™ PUR Adhesive TE031, Off-White, 2 kg

- 3M ID 7000028589

Details

Highlights

- Ideal for bonding polystyrene, polyacrylic and a wide variety of other plastics

- Rapid rate of strength build-up offers fast bonds for quick assembly

- Final cured strength over 6MPa

- 100% solids for quick and tough results without drying or ventilation equipment

- High plasticizer resistance for long-term performance

- One-component and moisture-curing adhesive reduces prep time

3M™ Scotch-Weld™ PUR Adhesive TE031 features rapid strength build-up and set time, producing strong bonds to a wide variety of plastics without drying or ventilation equipment. This extrudable grade adhesive is applied warm through a 3M™ Scotch-Weld™ PUR Adhesive Applicator or through bulk equipment specifically designed for use with PUR adhesives.

Reduced Prep Time, Quick Adhesion and Fast Set Time Featuring rapid strength build-up, 3M™ Scotch-Weld™ PUR Adhesive TE031 is a one-component, moisture-curing structural adhesive that offers a fast set time (30 seconds) and is ideal for bonding a wide variety of plastics including polystyrene and polyacrylic. As a 100% solids adhesive, our formula produces fast bonds with reduced prep time and provides high-strength and durable adhesion without the need of drying and ventilation equipment. Exceptionally strong, this adhesive provides over 6MPa. This fast handling strength adhesive has high plasticizer-resistance and can be used to bond heat-sensitive materials. Recommended Applications Wood or plastic decorative trip and moldings for furniture and cabinets Edge moldings for countertops, tables, shelving and desks Wood of MDF drawer bottoms, backs and facings Modular office wall partitions Interior and exterior wood and metal household door assembly Bond and seal wood or plastic stiles and rails in shutters Rubber insulation to wood, plastic or metal Fiberglass to wood in marine interiors Metal to laminated honeycomb in trade show booths Combines Structural Adhesive Benefits with Hot Melt Adhesive Speed Our family of one-part, moisture-curing Polyurethane Reactive (PUR) adhesives begins curing when exposed to moisture or humidity. Moisture-cure adhesives cure by means of a chemical and mechanical bond. Their high-tack properties provide a strong grab to surfaces while its reactivity creates a chemical bond to the surface as well. A moisture-cure urethane adhesive will chemically bond to the surface and leave a permanent residue if not removed quickly. Once cured, the adhesive can only be removed by mechanical means, such as grinding or sanding, which can degrade the original condition of the surface as it is removed. This chemical/mechanical bond is why moisture-cure urethanes are among the strongest adhesives available. They offer a highly aggr

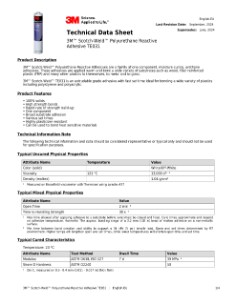

Typical Properties

| Adhesive Type | Urethane |

| Application Method | Extruded from hand held or bench mounted applicators |

| Brands | Scotch-Weld™ |

| Container Size (Metric) | 2 kg |

| Full Cure Time | 24 hr |

| Hardness | 50 Shore D |

| Industries | Furniture, General Industrial, Automotive, Consumer Goods, Packaging, Signage, Transportation, Construction, Electronics, Military and Government, Retail, Specialty Vehicle, Woodworking |

| Product Color | White |

| Product Form | Bag |

| Solids Weight Percent (Approximate) | 100 % |

| Storage Temperature (Celsius) | 16 to 27 °C |

| Units per Case | 6.0 |

| Viscosity | Self-leveling |

3M-Scotch-Weld-Polyurethane-Reactive-Adhesive-TE031.pdf

3M-Scotch-Weld-Polyurethane-Reactive-Adhesive-TE031.pdf