3M™ Cloth Belt 777F

- | Select product options for IDs.

Details

Highlights

- Ceramic aluminum oxide grain blend cuts faster and lasts longer than traditional aluminum oxide

- Produces more parts per belt than traditional aluminum oxide belts, requiring fewer belt changes

- Heavyweight polyester backing supports high-pressure applications and can be run wet or dry

- Contains a grinding aid to reduce heat and increase performance when grinding stainless steel

- Durable resin bond resists heat deterioration, which extends the life of the belt

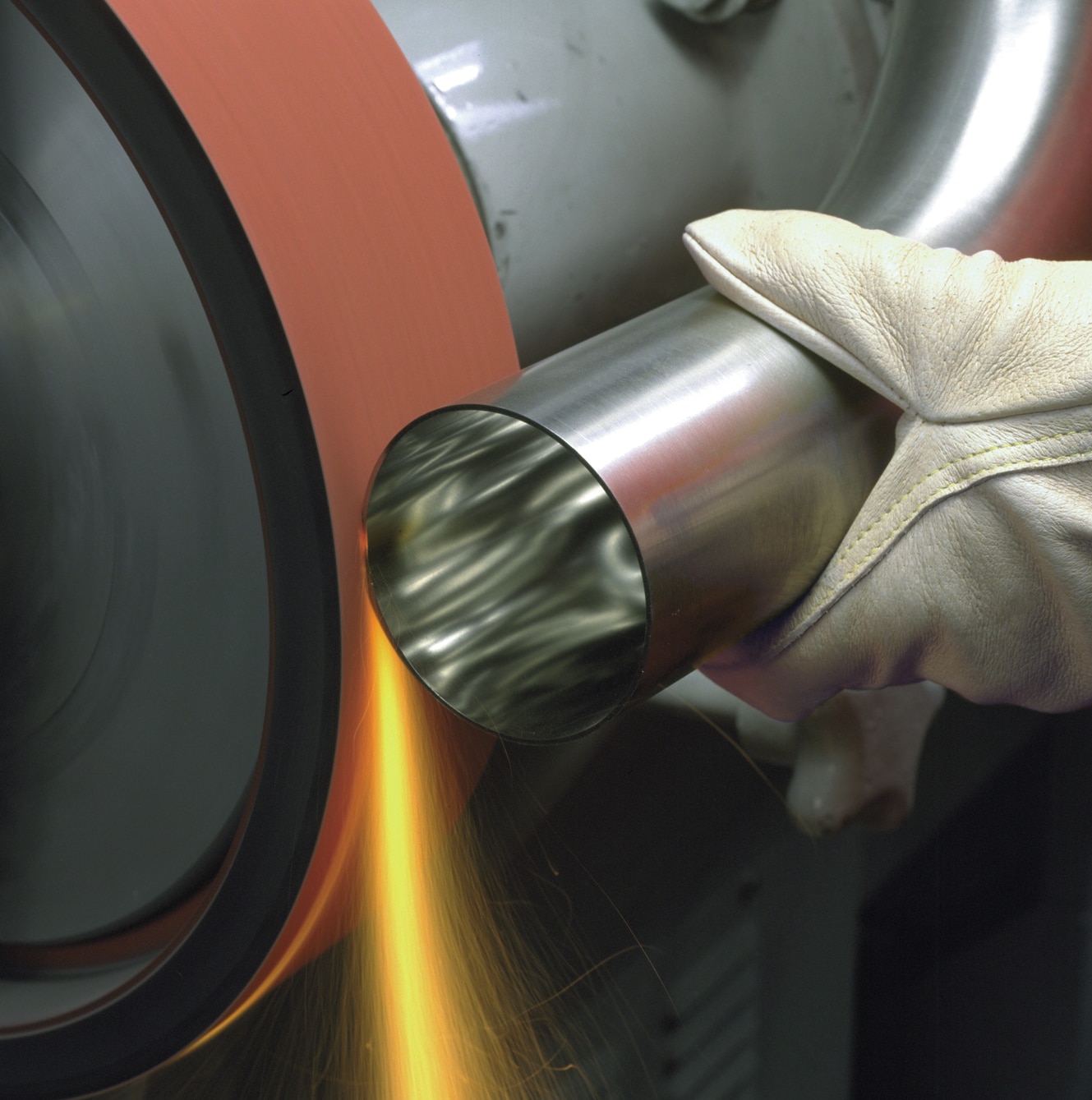

Take advantage of increased durability and cutting efficiency with 3M™ Cloth Belt 777F. This belt features a blend of 3M™ Ceramic Abrasive Grain and aluminum oxide that outperforms aluminum oxide belts in stock removal and metal finishing applications. The heavyweight cloth backing supports high-pressure applications, performs well on heat-sensitive metals, and can be used dry or with lubricant.

Grinding aid improves performance on stainless steel

Deburr, Blend and Finish Stainless Steel

3M™ Cloth Belt 777F contains a grinding aid that reduces running temperatures when used on heat-sensitive alloys like stainless steel, nickel alloys and cobalt alloys. The abrasive grain is bonded to the backing with resin to maintain durability under high heat and pressure. This belt is recommended for use on stainless steel or other exotic metal alloys for dimensioning parts, deburring, blending, and finishing castings and forgings.

Can be used to add a grain pattern on stainless steel

Ceramic Abrasive Grain Boosts Performance

For increased performance, 777F products feature aluminum oxide blended with 3M ceramic abrasive grain for a harder, longer-lasting abrasive. Ceramic/aluminum oxide blend surpasses aluminum oxide abrasives in cut-rate and durability and makes the Cloth Belt 777F an excellent choice for moderate stock removal and surface preparation.

Sized to Suit Your Needs

These abrasive belts are available in various widths and lengths for sanding both wood and metal. 3M offers a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough-cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

Find Your Flex

Belts come with various flexibilities and splices that join the belt ends. 3M™ Cloth Belt 777F has a film splice for added strength when grinding in high pressure applications. When greater flexibility may be needed to increase conformity or for a softer touch for finishing and blending, an L-flex provides more flexibility than the standard flex, and a fullflex belt is the most flexible.

Applications

- Moderate stock removal

- Deburring stainless steel

- Finishing stainless steel

- Surface preparation

Typical properties

| Abrasive Material | Ceramic Aluminum Oxide |

| Application | Grinding, Finishing, Deburring, Surface Preparation |

| Back Color | Brown |

| Backing Material | Polyester Cloth, Cloth |

| Backing Weight | YF Weight, X Weight |

| Bond Type | Resin |

| Brands | 3M™ |

| Equipment - Machines | File Belt Sanders, Manual Backstand, Stroke Sanders, Bench Top Motors, Inline Sanders, Wide Belt Sanders |

| Flex Type | Single-flex, L-flex |

| For Use On | Bronze, Cobalt & Nickel Alloy, Aluminum, Stainless Steel, Titanium/Zirconium, High Nickel Alloy, Brass, Carbon Steel, Titanium, Copper, Soft Metals, Hardened Steel |

| Grit | 36, 40, 50, 60, 80, P100, P120, P150, P180 |

| Industries | Metalworking, Marine |

| Product Color | Orange |

| Product Form | Belt |

| Splice Type | Fabri-lok, Film-lok, Sine-lok, Sine Wave, Lap Unskived |

| Sub Applications | Blending, Coating Removal, Weld Grinding, Shaping, Intermediate Finishing, Radiusing, Mill Scale Removal, Descaling, Straightline - Brushed Finish, Setting the Grain |

| Sub Industries | Metal Fabrication, Medical Instruments, Plumbing Fixtures, Builders Hardware, Turbine Engines, Plating & Polishing, Metal Implants |

| Overall Length (Imperial) | 2.81 in, 3.14 in, 3.93 in, 6.28 in, 6.34 in, 9.5 in, 10.688 in, 11 in, 11.625 in, 12 in, 15.5 in, 15.78 in, 17.75 in, 18 in, 18.75 in, 18.84 in, 18.87 in, 18.93 in, 20 in, 20.5 in, 24 in, 25.21 in, 30 in, 34 in, 36 in, 42 in, 44 in, 48 in, 51 in, 60 in, 72 in, 73 in, 74 in, 75 in, 76 in, 78.75 in, 79 in, 80 in, 84 in, 85 in, 88 in, 89 in, 90 in, 91 in, 100 in, 103 in, 106 in, 107 in, 118 in, 120 in, 126 in, 132 in, 135 in, 148 in, 156.75 in, 158 in, 168 in, 202 in, 248 in, 258 in, 264 in, 274 in, 300 in, 306 in, 310 in, 325 in, 328 in, 350 in, 354 in, 360 in, 362 in, 375 in, 376 in, 434 in, 444 in |

| Overall Length (Metric) | 71.374 mm, 79.756 mm, 99.822 mm, 159.512 mm, 161.036 mm, 241.3 mm, 271.475 mm, 279.4 mm, 295.275 mm, 304.8 mm, 393.7 mm, 400.812 mm, 450.85 mm, 457.2 mm, 476.25 mm, 478.536 mm, 479.298 mm, 480.822 mm, 508 mm, 520.7 mm, 609.6 mm, 640.334 mm, 762 mm, 863.6 mm, 914.4 mm, 1066.8 mm, 1117.6 mm, 1219.2 mm, 1295.4 mm, 1524 mm, 1828.8 mm, 1854.2 mm, 1879.6 mm, 1905 mm, 1930.4 mm, 2000.25 mm, 2006.5 mm, 2032 mm, 2133.6 mm, 2159 mm, 2235.2 mm, 2260.6 mm, 2286 mm, 2311.4 mm, 2540 mm, 2616.2 mm, 2692.4 mm, 2717.8 mm, 2997.2 mm, 3048 mm, 3200 mm, 3200.4 mm, 3299.4 mm, 3352.8 mm, 3429 mm, 3759.2 mm, 3981.45 mm, 4013.2 mm, 4267.2 mm, 5130.8 mm, 6299.2 mm, 6553.2 mm, 6705.6 mm, 6959.6 mm, 7620 mm, 7772.4 mm, 7874 mm, 8255 mm, 8331.2 mm, 8890 mm, 8991.6 mm, 9144 mm, 9194.8 mm, 9525 mm, 9550.4 mm, 11023.6 mm, 11277.6 mm |

| Overall Width (Imperial) | 0.125 in, 0.25 in, 0.375 in, 0.5 in, 0.75 in, 1 in, 1.25 in, 1.5 in, 1.75 in, 2 in, 2.5 in, 2.75 in, 3 in, 3.5 in, 4 in, 5 in, 5.375 in, 6 in, 8 in, 9 in, 12 in, 13 in, 18 in, 19 in, 25 in, 36 in, 37 in, 52 in, 65 in, 68 in, 76 in, 110 in, 126 in, 156.75 in |

| Overall Width (Metric) | 3.175 mm, 6.35 mm, 9.525 mm, 12.7 mm, 19.05 mm, 19.1 mm, 25.4 mm, 31.75 mm, 38.1 mm, 44.45 mm, 50.8 mm, 63.5 mm, 69.85 mm, 76.2 mm, 88.9 mm, 101.6 mm, 127 mm, 136.398 mm, 152.4 mm, 203.2 mm, 228.6 mm, 304.8 mm, 330.2 mm, 457.2 mm, 482.6 mm, 635 mm, 914.4 mm, 939.8 mm, 1320.8 mm, 1727.2 mm, 1930 mm, 1930.4 mm, 2794 mm |

Resources

Safety Data Sheets

Document Number: MSDS_2407336_US_EN

(PDF)

Reviews

Large Volume Order

Thank You!

Your form was submitted successfully.

Our Apologies...

An error has occurred while submitting. Please try again later...

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

3M™ Cloth Belt 777F

3M™ Cloth Belt 777F 3M™ Cubitron™ ll Cloth Belt 784F

3M™ Cubitron™ ll Cloth Belt 784F 3M™ Cubitron™ ll Cloth Belt 947A

3M™ Cubitron™ ll Cloth Belt 947A 3M™ Cloth Belt 767F

3M™ Cloth Belt 767F