Scotch-Brite™ Clean and Strip Unitized Wheel

- | Select product options for IDs.

Details

Highlights

- More effective, smoother running, and safer for coating and corrosion removal than wire wheels and cups

- Extra coarse abrasive and low conformability provide strong cutting action without damaging the base material

- Gets into hard-to-reach areas

- Tough, layered, unitized construction can operate clockwise or counterclockwise directions

- Resists heat buildup and loading on soft coatings, allowing prolonged operation and consistent coating removal

The Scotch-Brite™ Clean and Strip Unitized Wheel is a unitized wheel made for aggressive coating removal, cleaning welds, and removing rust, paint and coatings. The layered, durable unitized wheel construction and hard 7 density, with low conformability, make it a great match for edges, when durability is a must.

On right angle grinders and bench tools, Scotch-Brite™ Unitized Wheels produce great results

Remove Unwanted Coatings

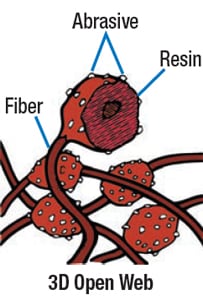

Among its features, Scotch-Brite™ Clean and Strip Unitized Wheel has a few abrasive elements that make it uniquely suited for applications like coating removal. First, it has a durable unitized construction that won't yield or deflect to surface irregularities, ensuring an ongoing, aggressive cut. Second, it is made with open web, which helps minimize clogging and loading when removing these coatings.

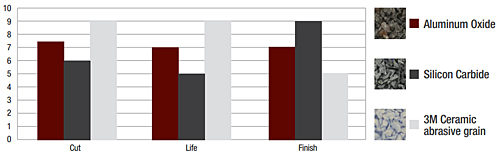

Peeling back the paint, here's how the Scotch-Brite™ Clean and Strip Unitized Wheel is engineered. To help with your toughest cleaning applications, we intersperse extra coarse (XCS) silicon carbide mineral on synthetic fibers using resin. The coarse grade helps the abrasive cut more aggressively than minerals of a finer grade. While silicon carbide breaks down faster than aluminum oxide, it produces a brighter finish. It cuts sharply to effectively remove scale, rust, surface contaminants, paints, coatings, weld discoloration and splatter.

The unitized construction of the Scotch-Brite™ Clean and Strip Unitized Wheel further lends itself to aggressive cutting action. To create a unitized wheel, we compress layers of open web material together during wheel production. Having multiple layers melded together enhances the abrasive's overall ability to aggressively tackle the substrate.

Resist Loading

Finally, the open web helps with the loading that is commonly found in high-production environments and during soft coating removal. Gaps between the nylon fibers permit debris to escape, minimizing loading and premature clogging — which, in turn, prolongs abrasive service life. As the fibers break down, they reveal fresh, sharp mineral, so you get a consistent cut — part after part.

This dense and durable wheel works well with a variety of portable tools, including die grinders, to reach tight or confined areas. When it comes to peeling back the paint, trust our Scotch-Brite™ Clean and Strip Unitized Wheel to help you unearth the layers underneath.

Find More Scotch-Brite™ Abrasives

Typical properties

| Abrasive Material | Silicon Carbide |

| Application | Grinding, Surface Preparation |

| Brands | Scotch-Brite™ |

| Center Hole Diameter (Imperial) | 0.188 in, 0.25 in, 0.375 in, 0.4375 in, 0.5 in, 0.625 in, 0.875 in, 1 in, 1.25 in |

| Center Hole Diameter (Metric) | 4.763 mm, 6.35 mm, 9.525 mm, 11.125 mm, 12.7 mm, 15.875 mm, 22.225 mm, 25.4 mm, 31.75 mm |

| Density | 7 |

| Density Rating | Hard |

| Equipment - Machines | Die Grinders, Centerless Grinders, Pressure Assit Backstand, Inline Sanders, Manual Backstand |

| Face Width (Imperial) | 0.25 in, 0.5 in, 0.75 in, 1 in |

| Face Width (Metric) | 6.35 mm, 12.7 mm, 19.05 mm, 25.4 mm |

| For Use On | All Metals |

| Grade | Extra Coarse |

| Industries | Metalworking, Marine |

| Maximum Speed | 3500 rpm, 5000 rpm, 7000 rpm, 10000 rpm, 14100 rpm, 20100 rpm, 25100 rpm, 35100 rpm |

| Product Color | Black |

| Product Form | Wheel |

| Sub Applications | Rust Removal, Paint Removal, Paint Stripping, Coating Removal, Slab Cleaning, Chrome Stripping |

| Sub Industries | Medical Instruments, Metal Implants, Plumbing Fixtures, Turbine Engines, Metal Fabrication, Builders Hardware |

| Overall Diameter (Imperial) | 1 in, 1.5 in, 2 in, 3 in, 4 in, 6 in, 8 in, 12 in |

| Overall Diameter (Metric) | 25.4 mm, 38.1 mm, 50.8 mm, 76.2 mm, 101.6 mm, 152.4 mm, 203.2 mm, 304.8 mm |

Resources

Safety Data Sheets

Document Number: MSDS_2658193_US_EN

(PDF)

Reviews

Large Volume Order

Thank You!

Your form was submitted successfully.

Our Apologies...

An error has occurred while submitting. Please try again later...

Related Products

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.