Scotch-Brite™ SST Unitized Wheel

- | Select product options for IDs.

Details

Highlights

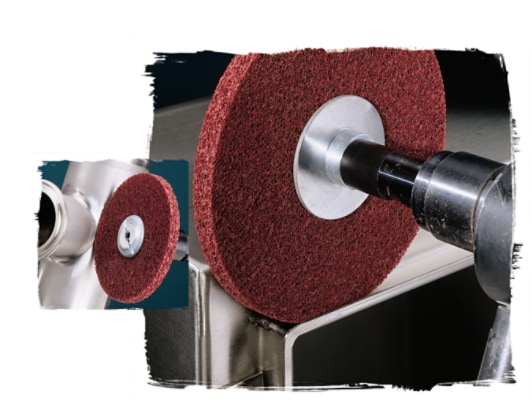

- Tough, layered unitized construction operates clockwise or counterclockwise

- Resists loading and runs cool, extending life of the wheel

- Perfect for very narrow widths and/or small diameters

- Higher densities retain conformability for finishing intricate shapes and contours

- Easy to run on smaller and portable equipment

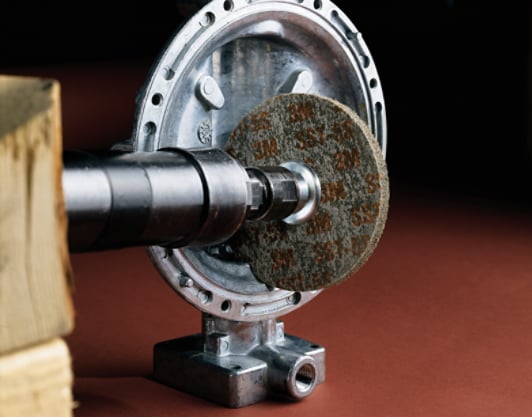

Scotch-Brite™ SST Unitized Wheels offer the same advantages as the SST convolute wheels. Softer and more conformable than many other higher density wheels, the SST is ideal for deburring and finishing demanding alloys like stainless steel and titanium. Unitized wheels can be made in much smaller diameters and widths than convolute wheels for more precise applications.

Designed for deburring stainless steel, titanium and other demanding alloys, Scotch-Brite™ SST Unitized Wheels provide uniform and repeatable results in applications requiring narrow widths and/or smaller diameters. Burrs left behind from machining operations like drilling, stamping and punching are easily removed from hard to reach areas, intricate geometries, precision edges and surfaces and high value materials.

Our Scotch-Brite™ SST Unitized Wheels are used extensively in the aerospace industry to deburr and finish aircraft engine components, to finish parts used in medical devices and surgical instruments and for mold and die polishing.

Built for Versatility

Available in three densities with silicon carbide or aluminum oxide abrasive mineral, this unitized version of the SST wheel runs well on bench motors, floor lathes, portable power tools and other smaller equipment.

Scotch-Brite™ uses proprietary technology to bind synthetic fibers and abrasive particles to create an abrasive system that delivers consistent results for the life of the product. The open web construction continually exposes fresh abrasive to the work surface, for a consistent finish.

Typical properties

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Deburring, Finishing |

| Attachment Type | Center Hole |

| Brands | Scotch-Brite™ |

| Center Hole Diameter (Imperial) | 0.125 in, 0.188 in, 0.25 in, 0.375 in, 0.5 in, 0.75 in, 1 in, 1.25 in, 3 in |

| Center Hole Diameter (Metric) | 3.175 mm, 4.763 mm, 6.35 mm, 9.525 mm, 12.7 mm, 25.4 mm, 31.75 mm, 76.2 mm, 195 mm |

| Density | 3 , 5 , 7 |

| Face Width (Imperial) | 0.125 in, 0.188 in, 0.25 in, 0.375 in, 0.5 in, 0.625 in, 0.75 in, 1 in |

| Face Width (Metric) | 3.175 mm, 4.763 mm, 6.35 mm, 9.525 mm, 12.7 mm, 15.875 mm, 19.05 mm, 25.4 mm |

| For Use On | Alloys like stainless steel and titanium |

| Grade | Fine |

| Industries | Medical Equipment, Aerospace |

| Maximum Speed | 3200 rpm, 3750 rpm, 5500 rpm, 6000 rpm, 7500 rpm, 10000 rpm, 12100 rpm, 14100 rpm, 15100 rpm, 18100 rpm, 22100 rpm, 30100 rpm, 35100 rpm |

| Product Color | Tan, Gray |

| Product Form | Wheel |

| Overall Diameter (Imperial) | 1 in, 1.5 in, 2 in, 3 in, 4 in, 6 in, 8 in, 10 in, 12 in, 14 in |

| Overall Diameter (Metric) | 25.4 mm, 38.1 mm, 50.8 mm, 76.2 mm, 101.6 mm, 152.4 mm, 203.2 mm, 254 mm, 304.8 mm, 355.6 mm |

Resources

Safety Data Sheets

Document Number: MSDS_1930189_US_EN

(PDF)

Safety Data Sheets

Document Number: MSDS_2602316_US_EN

(PDF)

Reviews

Large Volume Order

Thank You!

Your form was submitted successfully.

Our Apologies...

An error has occurred while submitting. Please try again later...

Related Products

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

Scotch-Brite™ SST Unitized Wheel

Scotch-Brite™ SST Unitized Wheel Scotch-Brite™ EXL Unitized Wheel

Scotch-Brite™ EXL Unitized Wheel