3M™ Microfinishing Film Roll 268L

- | Select product options for IDs.

Details

Highlights

- Provides precise, controlled, close-tolerance finishes

- High-strength film backing is tear resistant and can be run wet to reduce loading and airborne residue

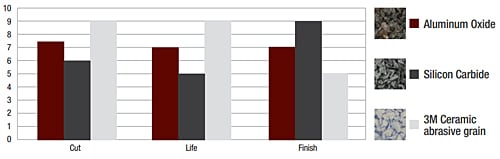

- Precision, micron-graded aluminum oxide abrasive offers a fast cut, long life, and uniform finish on many substrates

- Ideal for sanding plastics, paint, e-coat and wood, as well as ferrous and non-ferrous metals

The 3M™ Microfinishing Film Roll 268L is a fast-cutting abrasive for precise, uniform, close-tolerance finishes. Aluminum oxide is resin-bonded to a 3 mil, high-strength polyester film backing that provides durability and flexibility for consistent finishing on contoured surfaces. Use wet or dry.

See more Woodworking solutions. (PDF, 20.55 Mb)

Learn more about Metalworking solutions.(PDF, 12.95 Mb)

Run It Wet or Dry

Coolant generally extends abrasive life, increases cut rate, prevents loading, and reduces air-borne particles. The high-strength, bare-film backing maintains its strength and flexibility when run wet, while paper will disintegrate. Available in a range of grades to help operators achieve goal tolerances.

Typical properties

Resources

Reviews

Similar products

Current product  3M™ Microfinishing Film Roll 268L 3M™ Microfinishing Film Roll 268L | ||||

|---|---|---|---|---|

| Micron Grade | 9 μm, 15 μm, 20 μm, 30 μm, 40 μm, 50 μm, 60 μm, 80 μm, 100 μm | |||

| Product Form | Roll | |||

| Abrasive Material | Aluminum Oxide |

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

3M™ Microfinishing Film Belt 362L

3M™ Microfinishing Film Belt 362L 3M™ Microfinishing Film Roll 272L

3M™ Microfinishing Film Roll 272L 3M™ Microfinishing Film Roll 372L

3M™ Microfinishing Film Roll 372L