3M™ Paper Roll 364UZ

- | Select product options for IDs.

Details

Highlights

- F-weight heavy paper backing provides durability and smooth operation

- Static resistant treatment helps manage dust and loading

- Premium aluminum oxide mineral provides aggressive cut and long abrasive life

- Open coat provides fast stock removal

- Roll form enables easy customization for sanding blocks or drum sander applications

3M™ Paper Roll 364UZ is constructed with premium aluminum oxide mineral. It resists loading with an open-coat construction and is coated on an F-weight paper backing to efficiently sand and finish. F-weight is one of the heaviest, most rigid paper backings available and will achieve finer finishes than cloth backed sheets in the same grade.

Premium aluminum oxide mineral on a heavy F wt. paper

Premium aluminum oxide mineral on a heavy F wt. paper

The F-weight backing of our 3M™ Paper Roll provides smooth operation and durability. The abrasive side features an open coat structure. The open coat construction resists loading better than closed coat sheets, particularly on soft wood. This product also features our 3M dust management technology that reduces static cling in the dust particles, allowing them to be pulled away when coupled with an efficient dust collection system.

- Lighter Backings — finer grits for finishing or blending

- Heavier Backings — coarser grits for dimensioning or stock removal

Fast Cut, Long Life

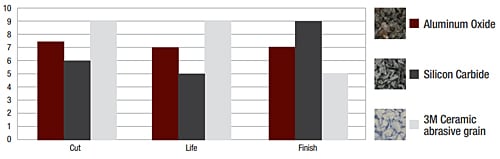

The 3M™ Paper Roll features a premium aluminum oxide abrasive, which is a popular choice among industrial professionals because of its cut-rate and long life. This mineral is a tough, durable abrasive that self-fractures to expose fresh cutting edges in use, whereas traditional abrasives, such as garnet, quickly wear down with use. Due to its high cut-rate, hardness, strength, and low heat retention, aluminum oxide mineral is widely used for sanding and finishing applications. Aluminum oxide is suitable on a wide variety of substrates in both woodworking (PDF, 20.55 Mb) and metalworking (PDF, 73.24 Mb), including ferrous alloys.

Typical properties

| Abrasive Material | Aluminum Oxide |

| Backing Weight | F Weight |

| Brands | 3M™ |

| Coat Type | Open Coat |

| Grit | 80, P100, P120, P220 |

| Industries | Woodworking |

| Product Color | Maroon |

| Product Form | Roll |

| Sub Industries | Primary Wood and Panel Processing |

Resources

Catalogs

(PDF , 73MB)

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

3M™ Industrial Products for Metalworking Catalog Hi Res PDF

3M™ Industrial Products for Metalworking Catalog Hi Res PDF