3M™ Flexible Diamond Sheet 6450J

- | Select product options for IDs.

Details

Highlights

- Diamond mineral abrasive

- Open dot construction helps minimize loading, prolonging abrasive service life

- Large and small open dot patterns available for applications where refined finishing and reduced loading are special concerns

- Metal bonding adds durability and long sheet life

- Type C cloth backing should be used with coolant

- Sheets may be cut and converted to fit unique project needs

3M™ Flexible Diamond Sheet 6450J features micron-graded diamond particles which are metal bonded to a strong yet flexible Type C backing for applications requiring flexibility. Two available open dot patterns allow for different requirements of stock removal and surface finishes. Sheet 6450J is suitable for hard-to-grind materials such as stone, glass, ceramic, carbide and composites.

Open dot construction helps minimize loading, prolonging abrasive service life

Open dot construction helps minimize loading, prolonging abrasive service life

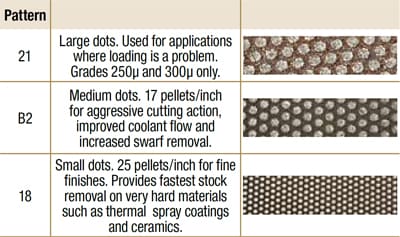

Our Open Dot Pattern: What Does it Mean?

The open dot pattern on each 3M™ Flexible Diamond abrasive product means that the diamond mineral particles are adhered to the backing in a series of small dots. This is designed to provide aggressive cutting action while also allowing consistent space for evacuation of stock particles during use, helping reduce loading and prolonging the life of the abrasive surface without sacrificing cut rates.

3M™ Flexible Diamond Sheet 6450J is available in two open dot patterns for a range of uses. Pattern 18 is a small dot pattern equating to 25 pellets per inch. It provides consistent stock removal on very hard materials such as thermal spray coatings and ceramics. The B2 Pattern, equating to 17 pellets per inch, is designed to deliver an aggressive cutting action with improved coolant flow and increased swarf removal.

Better Science for Better Sanding from 3M

Part of the 3M portfolio of Superabrasives, our 3M™ Flexible Diamond Sheet 6450J is an outstanding example of how 3M applies science to the lives of professionals in a range of specific industries where excellent grinding and finishing are critical. From its hard diamond mineral abrasive to its flexible cloth backing, it is built by 3M to help businesses like yours operate faster, better and more efficiently.

Recommended Applications

- Hand glass seaming

- Hard-to-grind materials

Typical properties

| Abrasive Material | Diamond |

| Application | Grinding, Sanding, Finishing |

| Backing Material | Cloth |

| Backing Type | C |

| Bond Type | Metal |

| Brands | 3M™ |

| Diamond Abrasive Pattern | 18 |

| Equipment - Machines | Cylindrical Grinders, Centerless Grinders, Bench Top Motors, Manual Backstand |

| For Use On | Carbide, Composites, Cast Iron, High Nickel Alloy, Ceramic, Oxides, Stone, Soft Metals |

| Industries | Aerospace, General Industrial, Transportation & Heavy Equipment, Metalworking |

| Micron Grade | M20, M125 |

| Product Color | White, Black |

| Product Form | Sheet |

| Sub Applications | Centerless & Cylindrical Grinding, Edge Seaming |

| Sub Industries | Builders Hardware, Medical Instruments, Metal Fabrication, Metal Implants, Plating & Polishing, Plumbing Fixtures, Turbine Engines |

Resources

Safety Data Sheets

Document Number: MSDS_1167709_US_EN

(PDF)

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.