3M™ Hookit™ Film Sheet 375L

- | Select product options for IDs.

Details

Highlights

- Durable film backing is tear-resistant and provides a uniform finish

- Flexible film sheet conforms smoothly to contours and rounded edges

- Versatile abrasive suits many applications for woodworking and paint prep

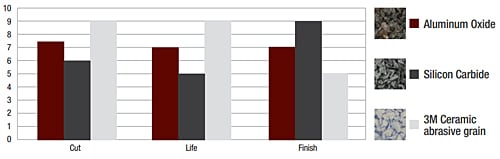

- Premium mineral delivers a faster cut and extended life

- Load-resistant coating and open coat construction help prevent clogging from dust and debris

- Easy-to-use 3M™ Hookit™ attachment system enables quick product change-outs

3M™ Hookit™ Film Sheet 375L is made to deliver outstanding tear resistance, flexibility and consistent finish on a variety of substrates. The film backing conforms to contours and delivers a super smooth application that produces a highly uniform finish. Premium aluminum oxide grain offers a faster cut and extended product life over standard A/O mineral for greater productivity.

The Hookit™ hook-and-loop feature makes sheet attachment, removal, and re-attachment clean and easy, and facilitates use and re-use of the sheet for the full extent of its abrasive life. Hookit™ sheets have J-shaped hooks of the type most commonly used in everyday hook-and-loop applications. Hookit™ sheets grip the brushed nylon loop backings of 3M™ Hookit™ disc pads, file shoes and blocks. It's simple: just set the sheet in place and start sanding. The sheet removes just as cleanly and easily. The Hookit™ system is designed for work spaces and applications where adhesive backed sheets may become contaminated by dust, dirt, or flying debris.

3M Technologies Deliver Optimal Performance

3M™ Film Sheet 375L line of products was created with the commitment to help customers achieve superior productivity and performance while improving ease of use. 3M™ Hookit™ Film Sheet 375L is a convenient, reliable, high-performing, and long-lasting solution for many different applications, and is a great example of how 3M technologies enhance industrial productivity. Designed as the ultimate versatile solution, 375L film abrasives redefine what's possible and deliver the superior sanding capabilities that 3M customers world-wide have come to expect.

Learn More about the 3M™ 375L Line (PDF, 3,31 Mb)

| Selection Guide | Substrate | Application | Metal Type | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product | Mineral Type | Backing | Weight | Load-Resistant/ Grinding Aid |

Gel Coat |

Composites |

Solid Surface |

E-Coat |

Primer/Paint Prep |

Wood |

Metal |

Grinding |

Blending |

Deburring |

Finishing |

Aluminum |

Carbon Steel |

Non-Ferrous (Brass/Bronze) |

Stainless Steel |

|

| Good | NX | Aluminum Oxide | Paper | C/D | Y | • | • | • | • | • | • | • | • | • | ||||||

| 216U | Aluminum Oxide | Paper | A | Y | • | • | • | • | • | • | • | • | • | • | • | • | ||||

| 255L | Aluminum Oxide | Film | Film | Y | • | • | • | • | • | • | • | • | • | • | • | • | ||||

| 426U | Silicon Carbide | Paper | A | Y | • | • | • | • | • | |||||||||||

| 202DZ | Aluminum Oxide | Cloth | J | N | • | • | • | • | • | • | • | |||||||||

| UPGRADED! | 236U | Aluminum Oxide | Paper | C | Y | • | • | • | • | • | • | • | • | • | • | • | • | |||

| Better | 348D | Aluminum Oxide | Cloth | X | N | • | • | • | • | • | • | • | • | |||||||

| 360L | Aluminum Oxide | Film | Film | N | • | • | • | • | • | • | • | |||||||||

| 363I | Aluminum Oxide | Paper | F | N | • | • | • | • | • | • | • | • | • | |||||||

| NEW! | 375L | Aluminum Oxide | Film | Film | Y | • | • | • | • | • | • | • | • | • | • | • | • | |||

| Best | 366L | Aluminum Oxide | Film | Film | Y | • | • | • | • | • | • | • | • | • | • | • | ||||

| 735U | Blended Ceramic Aluminum Oxide |

Paper | C | Y | • | • | • | • | • | • | • | • | • | • | • | |||||

| 777F | Blended Ceramic Aluminum Oxide |

Cloth | Y | Y | • | • | • | • | • | • | • | • | • | |||||||

| 900DZ | Ceramic | Cloth | J | N | • | • | • | • | • | • | • | • | • | |||||||

Typical properties

Resources

Reviews

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.