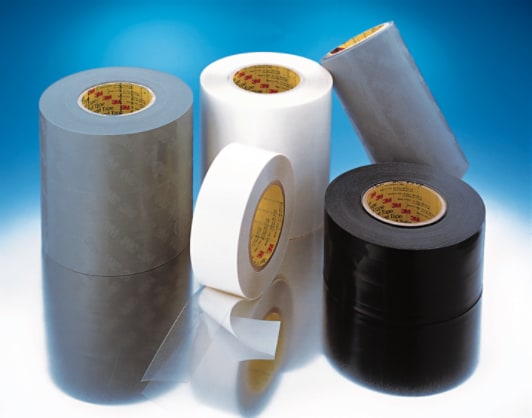

3M™ Polyurethane Protective Tape 8560

- | Select product options for IDs.

Support from 3M

3M is constantly working to meet the evolving challenges of the aerospace industry professionals worldwide. If you need help finding and existing solution or would like to talk about ideas your working on, get in touch with us.

Details

Highlights

- Tough, thermoplastic polyurethane elastomer has a high peel strength and is resistant to minor abrasion, scratch, erosion, tear and puncture

- Indoor grade polyurethane tape

- Thin and conformable tape is easy to apply and conforms over curved surfaces

- Can be painted over, or applied to painted surfaces

- Adheres to a wide variety of substrates and retains a constant level of adhesion over time, yet removes easily when necessary

3M™ Polyurethane Protective Tape 8560 is a 14 mil, leading edge erosion protection tape comprised of a tough polyurethane backing. It offers resistance to punctures, tearing and abrasion, This indoor polyurethane tape is qualified to aerospace specifications.

3M™ Polyurethane Protective Tapes are constructed from durable aerospace grade polymer, coated with a high performance, pressure-sensitive adhesive

Resists Wearing, Abrasion and Tearing

3M™ Polyurethane Protective Tape 8560 is a transparent thermoplastic polyurethane elastomer tape designed to provide premium leading edge erosion protection. It features scratch, tear, erosion and puncture resistance that comes from the polyurethane backing. The 8560 comes with a polyethylene liner. It can withstand a wide variety of difficult conditions. The tape can be applied efficiently in aircraft production and maintenance.

Our Best for Your Best

3M is proud to partner with organizations across the spectrum of aerospace and related industries. Enabling efficiencies, reducing process times and lowering aircraft weight is how we execute our never-ending mission to offer best-in-class adhesives, sealants, surface protection products and composite resins that effectively reduce costs on multiple fronts. Professionals across the industry know the numerous advantages of 3M Aerospace. Our brand is widely recognized for the highest standards of quality and performance, adding value to the final results. By engineering reliability, longevity and value into all of our products, we have a history of saving money by reducing waste, rework and time.

Learn More about 3M Aerospace Surface Protection Portfolio (PDF, 3.02 Mb)

3M maintaints partnerships with every major aircraft OEM in the world. Find your spec today.

Typical properties

| Adhesion Strength (Imperial) | 25 lb. |

| Adhesive Type | Pressure-sensitive |

| Application | Surface Protection, Erosion Protection |

| Backing Material | Polyurethane, Polyethylene |

| Backing Thickness (Imperial) | 12 mil |

| Backing Thickness (Metric) | 0.3 mm, 0.31 mm |

| Case Quantity | 1.0, 2.0, 3.0, 6.0, 9.0 |

| Maximum Operating Temperature (Celsius) | 82 ℃ |

| Maximum Operating Temperature (Fahrenheit) | 180 ℉ |

| Minimum Installation Temperature (Celsius) | 15.0 Degree Celsius |

| Minimum Installation Temperature (Fahrenheit) | 60.0 Degree Fahrenheit |

| Minimum Operating Temperature (Celsius) | -40 ℃ |

| Minimum Operating Temperature (Fahrenheit) | -40 ℉ |

| Product Color | Transparent |

| Tensile Strength (Imperial) | 75.0 lb/in |

| Tensile Strength (Metric) | 1313 N/100mm |

| Total Tape Thickness without Liner (Imperial) | 14 mil |

| Total Tape Thickness without Liner (Metric) | 0.36 mm |

| Overall Length (Imperial) | 36 yd |

| Overall Length (Metric) | 32.9 m |

| Overall Thickness (Imperial) | 0.014 mil, 14 in |

| Overall Thickness (Metric) | 0.356 mm |

| Overall Width (Imperial) | 1 in, 2 in, 3 in, 4 in, 6 in |

| Overall Width (Metric) | 25.4 mm, 50.8 mm, 76.2 mm, 101.6 mm, 152.4 mm |

Resources

Regulatory Data Sheet

Document Number: MSDS_1822949_US_EN_RDS

(PDF)