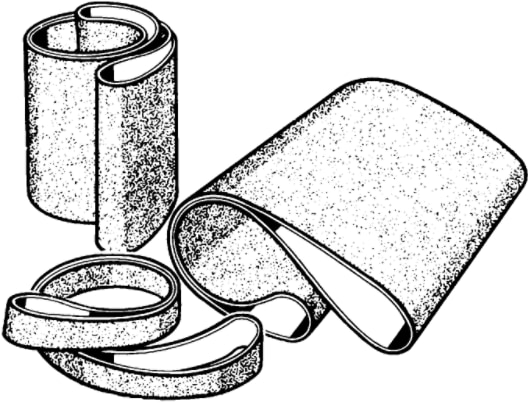

3M™ Cloth Belt 461F

- | Select product options for IDs.

Details

Highlights

- Sharp silicon carbide mineral cuts faster than aluminum oxide and produces a consistent finish

- Tough, water-resistant polyester backing supports wet or dry applications from heavy-duty grinding to fine finishing without tearing or nicking

- Cloth backing provides flexibility

- Heat-resistant resin coating bonds abrasive to backing for durability under pressure, heat, and water

- Use on backstands for grinding and finishing applications

3M™ Cloth Belt 461F is constructed of sharp silicon carbide abrasive that fractures easily and consistently produces an excellent finish for the duration of the belt life. This resin-bonded cloth belt gives you flexibility, durability, and consistent performance for grinding, blending, deburring, and finishing on all metals.

Heavy cloth backing provides extended belt life and high tear resistance

3M™ Cloth Belt 461F is frequently used for coarse grade grinding on stainless steel and titanium, as well as for glass polishing. The heavy polyester cloth backing provides rugged durability and tear-resistance, and is suitable for wet or dry applications. Belts come in both YF-weight polyester and XF-weight polyester.

Superior Finish Sanding with Silicon Carbide

Silicon carbide is a very hard and sharp mineral commonly used for low-pressure applications such as paint prep and the final stages of whitewood sanding, as well as grinding applications on metal. It can also be used for glass and mirror grinding, finishing, and polishing. While it may have a shorter life than aluminum oxide, it produces a superior finish and should be used where the best possible finish is desired.

For use on backstand, benchtop, slack of belt, flat finishing, centerless and wet roll grinding equipment

Belt Sizes for Every Application

Abrasive belts come in many different widths and lengths and are used on a variety of different belt sanding tools for many different applications on both wood and metal. At 3M we offer a broad selection of belts to fit most any industrial belt sander. Wider belts are used with wide belt sanders to dimension or finish wood panels, smooth rough cut edges of metal sheets, or add a grain pattern to stainless steel sheets. Medium-width belts fit onto edge sanders for sanding flat, narrow surfaces such as panel edges; and narrow belts are used with portable belt sanders for sanding or blending wood pieces such as cabinet doors.

To select the best product for your application, check out our easy-to-use 3M Belt Selection Guide (PDF, 113 Kb).

3M Engineered for Optimal Performance

3M Abrasives engineers know abrasive construction. For more than 100 years 3M has been a leading abrasive supplier for the metalworking and woodworking industries, and we offer a complete line of high quality abrasive solutions to meet your unique needs. 3M™ Cloth Belt 461F was developed to help you deliver the best possible finish on metal surfaces. It is yet another example of how 3M science provides improved solutions for industrial applications.

Typical properties

| Abrasive Material | Silicon Carbide |

| Application | Deburring, Finishing, Grinding |

| Back Color | Gray |

| Backing Material | Polyester, Cloth, Polyester Cloth |

| Backing Weight | XF Weight, YF Weight |

| Bond Type | Resin |

| Brands | 3M™ |

| Equipment - Machines | Bench Top Motors, Wide Belt Sanders, Cylindrical Grinders, Manual Backstand, Stroke Sanders |

| Flex Type | Single-flex |

| Grit | P36, P60, P80, P100, P120, P150, P180, P220, P240, P320, P400, P600 |

| Product Color | Black |

| Product Form | Belt |

| Splice Type | Sine-lok, Film-lok, Fabri-lok |

| Sub Applications | Centerless & Cylindrical Grinding, Radiusing, Intermediate Finishing, Flat Finishing, Shaping, Blending, Fine Finishing |

| Overall Length (Imperial) | 36 in, 54 in, 64 in, 75 in, 90 in, 96 in, 106 in, 110 in, 118 in, 126 in, 131 in, 132 in, 138 in, 148 in, 156 in, 156.75 in, 165 in, 189 in, 243 in, 256 in |

| Overall Length (Metric) | 914.4 mm, 1371.6 mm, 1625.6 mm, 1905 mm, 2286 mm, 2438.4 mm, 2692.4 mm, 2794 mm, 2997.2 mm, 3200.4 mm, 3327.4 mm, 3352 mm, 3352.8 mm, 3505.2 mm, 3759.2 mm, 3962.4 mm, 3981.45 mm, 4191 mm, 4800.6 mm, 6172.2 mm, 6502.4 mm |

| Overall Width (Imperial) | 2 in, 3 in, 3.5 in, 4 in, 6 in, 26 in, 37 in, 52 in, 57 in, 62 in, 63 in, 65 in |

| Overall Width (Metric) | 50.8 mm, 76.2 mm, 88.9 mm, 101.6 mm, 152.4 mm, 660.4 mm, 939.8 mm, 1320.8 mm, 1447.8 mm, 1574.8 mm, 1600.2 mm, 1651 mm |

Resources

Safety Data Sheets

Document Number: MSDS_2406643_US_EN

(PDF)

Safety Data Sheets

Document Number: MSDS_3274057_US_EN

(PDF)

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.