3M™ Scotch-Weld™ Structural Adhesive Film AF 143-2, .100 wt, 40 in x 50 yd, 1 Roll/Case

- Part Number AF 143-2

- 3M Product Number AF 143-2

- 3M ID 7100064959

Support from 3M

3M is constantly working to meet the evolving challenges of the aerospace industry professionals worldwide. If you need help finding and existing solution or would like to talk about ideas your working on, get in touch with us.

Details

Highlights

- Designed for 350°F (175°C) cure

- For the bonding of honeycomb and metal to metal components where high strengths at 350°F (177°C) are required

- Excellent performance in the -67°F to 350°F (-55°C to 177°C) temperature range

- Includes an embossed liner

- Tan in color

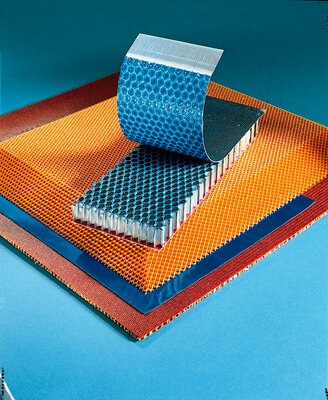

3M™ Scotch-Weld™ Structural Adhesive Film AF 143-2 is designed for the bonding of honeycomb and metal to metal components where high strengths at 350°F (177°C) are required. It provides excellent performance in the -67°F to 350°F (-55°C to 177°C) temperature range.

Many of adhesive films are designed to bond composite panel or honeycomb sandwich panels for a variety of structural applications

3M™ Scotch-Weld™ Structural Adhesive Film AF 143-2 provides excellent performance with easy-to-use shop handling properties. This adhesive film meets a range of needs without imposing excess material costs. AF 143-2 provides a reliable, long-term bond suitable for composites, metals in solid panel and honeycomb sandwich fabrication.

The following 3M primer is compatible with AF 143-2:

3M™ Scotch-Weld™ Structural Adhesive Primer EC-3917

Our heat-curing, easy handling film is designed to meet numerous customer specs in aerospace manufacturing. AF 143-2 supplies high fracture toughness and peel strength through a spectrum of environmental conditions and is easy to work with. Once cured it provides high bond strength from -67°F to 350°F (-55°C to 175°C) for use in challenging designs in multiple environments.

What is Structural Adhesive Film?

The fewer rivets you have in your aircraft the better. Structural adhesive films enable the designer to get more innovative with their parts, and reduce the overall number of rivets required on your structure. This thermosetting modified epoxy in film form can be used for bonding a wide variety of substrates, including metal, honeycomb and composite. Structural Adhesive Films come in a variety of weights and thicknesses, minimizing the weight while maintaining the structural integrity.

Compare More Structural Adhesive Films for Aerospace

The films are available in supported versions, which are typically used for monolithic bonding or honeycomb sandwich. They are also available in unsupported form for reticulation onto honeycomb. These films can be cured from temperatures as low as 180°F to as high as 350°F. Because these films are less messy and don't required mixing, they offer efficiencies in the design process. They are easier to use than typical paste adhesives.

3M is on the Leading Edge of Innovation

Adhesive bonding enables a more lightweight structure because it allows you to use more lightweight composite, as opposed to the metallic materials that were used in previous designs. Structural adhesive films are employed anywhere you are trying to bond metal to composite. This offers good erosion performance while minimizing weight.

Our Best for Your Best

3M is proud to partner with organizations across the spectrum of aerospace and related industries. Creating efficiencies, reducing process times and lowering aircraft weight is how we execute our never-ending mission to offer best-in-class adhesives, sealants and other products that effectively reduce costs on multiple fronts.

Learn More about 3M Aerospace

3M maintaints partnerships with every major aircraft OEM in the world. Find your spec today.

Typical properties

| Adhesive Type | Epoxy |

| Application | Bonding, Structural Bonding |

| Brands | Scotch-Weld™ |

| Cure Rate | 1 hr |

| Curing Temperature (Celsius) | 177 ℃ |

| Curing Temperature (Fahrenheit) | 350 ℉ |

| Maximum Operating Temperature (Celsius) | 177 ℃ |

| Maximum Operating Temperature (Fahrenheit) | 350 ℉ |

| Minimum Operating Temperature (Celsius) | -55 ℃ |

| Minimum Operating Temperature (Fahrenheit) | -67 ℉ |

| Nominal Weight (Imperial) | 0.1 lb/ft² |

| Product Color | Off-white |

| Product Form | Roll |

| Storage Environment | Freezer Storage |

| Substrate | Metal |

| Overall Length (Imperial) | 50 yd |

| Overall Length (Metric) | 45.7 m |

| Overall Width (Imperial) | 40 in |

| Overall Width (Metric) | 1 m |

Resources

Safety Data Sheets

Document Number: MSDS_1059385_US_EN

(PDF)