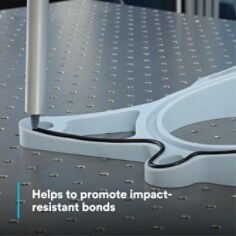

3M™ Scotch-Weld™ Acrylic Adhesive Accelerator A3-2 is the accelerator (Part A) of a two-part acrylic adhesive, engineered to be used with a B/A system. We designed this accelerator for use with our 3M™ Scotch-Weld™ Acrylic Adhesives in the DP8600, DP8700 and DP8900 Series. The fast rate of cure provides rapid strength build-up and produces tough, impact-resistant bonds.

Quick Rate of Cure Provides Fast Strength Build-Up

3M™ Scotch-Weld™ Acrylic Adhesive Accelerator A3-2 is the accelerator (Part A) designed to be mixed with the base (Part B) for a two-part acrylic adhesive, a B/A system (base acrylic adhesive sold separately). With a 10:1 mix ratio, this accelerator features an exceptionally fast rate of strength build-up, providing structural strength in minutes. We formulated this system to produce tough, durable, impact-resistant bonds as well as a non-sag adhesive for accurate application. These toughened products offer excellent shear, peel and impact performance. They provide improved adhesion to many plastics and metals, including those with slightly oily surfaces. Selected, Part B, acrylic adhesives include: DP8600, DP8700, DP8900 Series.

Recommended Applications

- Metalworking such as HVAC, appliance, sporting goods, and specialty vehicles

- Sign manufacturing such as panel to frame bonding, trim attachment, letter bonding, and frame assembly

- Bonding plastics, composites and powder coats to metal

Formulated to Produce Tough, Impact-Resistant Bonds for Durability

Formulated as part of a tough, reliable solution, 3M™ Scotch-Weld™ Acrylic Adhesive Accelerator A3-2 quickly produces the shear, peel and impact performance for those demanding applications that require fast results. For structural strength in minutes, look no further than the engineering of 3M, putting science to work.

Easy Adhesion with Acrylic

Acrylic adhesives (PDF, 5.9 Mb), often referred to as epoxy adhesives or epoxy glue, are two-part adhesives that provide excellent bond strength and durability, although slightly lower adhesion than 2 part epoxy in some situations. However, acrylic glues have several features that make them easier to use, including a much faster cure speed, higher tolerance for oily or unprepared bonding surfaces and the ability to bond a wide variety of materials, including nearly all plastics. Newer acrylic adhesive formulations are room temperature stable with a moderate shelf life.

Learn More about the 3M™ Two-Component Adhesive Sealant System (PDF, 3.6 Mb)