3M™ Microfinishing Film Disc 366L

- | Select product options for IDs.

Details

Highlights

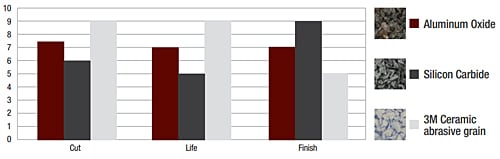

- Precision, micron-graded aluminum oxide offers a fast cut, long life and uniform finish on many substrates

- Durable polyester film backing provides flexibility for consistent finishing on contoured surfaces

- Load-resistant coating prevents dust and debris from clogging the disc

- May be run wet or dry

3M™ Microfinishing Film Disc 366L features the right blend of abrasive components, micron-graded aluminum oxide mineral, polyester backing and anti-load coating to make it a great disc for dust-generating substrates. It’s engineered to keep cutting sharp – despite the debris.

Fight Dust and Debrisces

When running the abrasive wet doesn't make sense for your application, there's an anti-loading stearate coating designed to help minimize loading. It breaks down gradually during sanding to remove dust and debris away from the abrasive, preventing mineral clogging and premature dulling. We engineered 3M™ Microfinishing Film Disc 366L with evenly spaced minerals, which helps evacuate sawdust and other sanding debris. Designed for use with orbital and random orbital sanders, the discs come in a range of micron grades for complete multi-step sanding and finishing.

Learn more about Sanding products. (PDF, 2.65 Mb)

Altogether, our 3M™ Microfinishing Film Disc 366L enables industrial professionals to capitalize on the benefits of a great microfinishing film that fights loading. Focus less on dust and debris and more on your top priority: your work.

Typical properties

Resources

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.