3M™ Microfinishing Film Disc 468L

- | Select product options for IDs.

Details

Highlights

- Silicon carbide mineral produces consistent finishes

- Ideal for sanding metals, plastics, wood, paint, e-coat and composites

- Strong 3 mil polyester film backing

- Open coat construction provides aggressive cut and reduced loading

- Use wet or dry

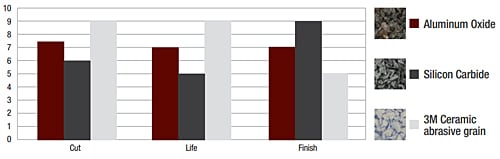

3M™ Microfinishing Film Disc 468L is designed to help you get the finest finish possible, is unbacksized to allow for operator customization. It features micron-graded silicon carbide abrasive bonded to a durable polyester film backing to produce a fast cut-rate and uniform finish on wood, composites, plastic, fiberglass and metal.

3M Abrasives for Finer Finishes Microfinishing — an important application for many operators — corrects the geometry of parts to close tolerance and creates fine finishes. Microfinishing can remove damaged or amorphous layers to improve the surface finish and roundness of the part. With films available in a variety of grades, operators should consider target tolerances when selecting the right microfinishing disc.

Typical properties

Resources

Reviews

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.