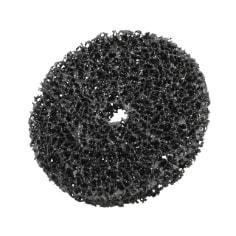

Scotch-Brite™ Clean and Strip Disc

- | Select product options for IDs.

Details

Highlights

- Removes paint, rust and coatings quickly without compromising the geometry of the workpiece

- Thin width gets into tight corners for complete cleaning, stripping, and surface prep

- Provides greater surface area than wire brushes

- Extra coarse (XCS) grade silicon carbide provides aggressive cutting and leaves a finish than wire brushes

- Load and heat resistance offers prolonged operation and consistent finishing results throughout disc life

- Smear resistant, non-woven web material provides uniform wear over the life of the disc

Scotch-Brite™ Clean and Strip Disc was designed to help operators tackle tough metalworking challenges: think paint prep and coating and corrosion removal. When removing unwanted contaminants and stubborn imperfections – or smoothing a rough surface – it’s a good idea to have a load-resistant, sharp-cutting abrasive on hand.

Paint Stripping Application

Scotch-Brite™ Clean and Strip Disc has all the benefits operators have come to expect from Scotch-Brite™ abrasives, including good load resistance and consistent cutting action. In fact, its ability to withstand debris makes it a good match for high-production environments and projects that generate a lot of dust, such as coating and corrosion removal. Scotch-Brite™ Clean and Strip Disc features a standard attachment system and may be connected to a backstand, right angle grinder or die grinder.

Corrosion Removal Application

Nylon fibers on Scotch-Brite™ Clean and Strip Disc are interspersed with extra-coarse (XCS) silicon carbide mineral. We chose extra-coarse (XCS) mineral, because it cuts more aggressively than minerals in a finer grade. Among synthetic minerals, silicon carbide is one of the sharpest. It breaks down faster than aluminum oxide but leaves a finer finish.

The Many Benefits of Scotch Brite™ Abrasives

As a Scotch-Brite™ product, this disc is engineered with open nylon web, which is why it's such a great match for cleaning welds, removing rust and stripping paint. The gaps between nylon fibers permit debris to escape. The benefits of this are twofold. First, it enhances the abrasive's ability to withstand loading.

Stripping Application

Typical properties

| Abrasive Material | Silicon Carbide |

| Application | Surface Preparation, Cleaning |

| Attachment Type | Hook & Loop |

| Backing Material | Non-woven |

| Brands | Scotch-Brite™ |

| Center Hole Diameter (Imperial) | 0.25 in, 0.375 in, 0.5 in, 0.625 in, 0.875 in, 1.25 in |

| Center Hole Diameter (Metric) | 6.35 mm, 9.398 mm, 12.7 mm, 15.748 mm, 22.098 mm, 31.75 mm |

| Equipment - Machines | Manual Backstand, Die Grinders, Right Angle Grinders |

| Grade | Extra Coarse |

| Industries | MRO, Transportation & Heavy Equipment, Aerospace, General Industrial, Metalworking, Marine |

| Maximum Speed | 1600 rpm, 3000 rpm, 3300 rpm, 4000 rpm, 5000 rpm, 6000 rpm, 8500 rpm, 12000 rpm |

| Sub Applications | Rust Removal, Paint Removal, Coating Removal, Sealant Removal, Paint Stripping |

| Sub Industries | Metal Fabrication |

| Overall Diameter (Imperial) | 2 in, 3 in, 4 in, 5 in, 6 in, 7 in, 8 in, 14 in |

| Overall Diameter (Metric) | 50.8 mm, 76.2 mm, 101.6 mm, 127 mm, 152.4 mm, 177.8 mm, 203.2 mm, 355.6 mm |

Resources

Safety Data Sheets

Document Number: MSDS_0687285_US_EN

(PDF)

Reviews

Large Volume Order

Thank You!

Your form was submitted successfully.

Our Apologies...

An error has occurred while submitting. Please try again later...

Related Products

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

Scotch-Brite™ Clean and Strip Disc

Scotch-Brite™ Clean and Strip Disc Scotch-Brite™ Clean and Strip Bonded Cleaning Brush, CS-CB, 7S Extra

Coarse, Config

Scotch-Brite™ Clean and Strip Bonded Cleaning Brush, CS-CB, 7S Extra

Coarse, Config