Scotch-Brite™ Match and Finish High Strength Flap Brush

- | Select product options for IDs.

Details

Highlights

- Flap construction reduces risk for chatter

- Easy-thread on/off attachment

- Aluminum oxide cuts sharp and leaves a soft scratch pattern

- Open web is load resistant, prolonging abrasive service life

- Open web is spongy and responds to surface irregularities of the part

Scotch-Brite™ Match and Finish High Strength Flap Brush is durable and aggressive, great for blending and finishing on a variety of metals.

Easy-thread on/off attachment

Restoring Finishes

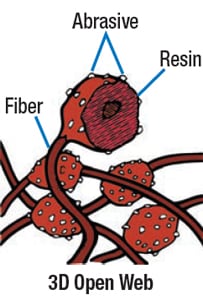

Scotch-Brite™ Match and Finish High Strength Flap Brushes combine aluminum oxide mineral and our non-woven nylon fibers with resin. Sharp-cutting aluminum oxide mineral leaves a fine finish, while the spongy, open web responds to surface irregularities and maintains part geometry. This brush is one of the most durable among all the Scotch-Brite™ flap brushes (PDF, 500 Kb), so it's good for graining stainless steel, blending handling marks and imperfections, cleaning around welds and light deburring.

Easy Attachment

Scotch-Brite™ Match and Finish High Strength Flap Brush may be used on the 3M 1HP Match & Finish Sander (sold separately) and is available in 5/8-11 threaded inserts for easy thread on/off attachment as well as a 4-way keyway attachment system.

Under normal use (abiding by recommended RPM), the Scotch-Brite™ Match and Finish High Strength Flap Brush minimizes chatter risk. As the brush spins, flaps rotate centrifugally and make continuous contact with the workpiece. By lapping the surface, the flaps reduce the residual traces or marks that tend to be left by singular discs or discs ganged on a shaft.

| Diameter | CP-FB | CF-FB | HS-FB | CB-FB |

| 6" | 4,000 | 3,400 | 3,400 | 3,400 |

| 8" | 4,000 | 3,200 | 3,200 | 3,200 |

| 10" | 3,200 | 2,500 | 2,500 | 2,500 |

| 12" | 2,700 | 2,500 | 2,500 | 2,500 |

| 14" | 2,000 | 2,000 | 2,000 | 2,000 |

| 16" | 1,900 | 1,500 | 1,500 | 1,500 |

CP-FB = Cut and Polish Flap Brush

CF-FB = Finishing Flap Brush

HS-FB = High Strength Flap Brush

CB-FB = Combi Flap Brush

The Many Benefits of Open Web Abrasives

Non-woven technology makes our Scotch-Brite™ industrial abrasives unique. A combination of fiber strands, resin, and abrasive mineral forms a thick, open web. The spring-like nature of the fibers responds to contours and effectively removes unwanted burrs, soils, and contaminants while maintaining the geometry of the workpiece, which in turn reduces rework and boosts productivity. Gaps in the web allow swarf to escape, so debris does not clog the mineral. Fibers in the web continually break down with use to reveal fresh mineral for exceptional consistency, superior cut performance, and extremely long service life. Scotch-Brite products not only enhance productivity, but also increase operator safety by reducing the need for cleaning chemicals and pastes, and replacing wire brushes that can break off and cause injury. From aesthetic finishing to weld blending, deburring, and more, Scotch-Brite abrasives work fast and deliver consistent results, part after part.

Learn More about the Scotch-Brite™ Match and Finish System (PDF, 1.3 Mb)

Typical properties

| Abrasive Material | Aluminum Oxide, Silicon Carbide |

| Application | Polishing, Finishing |

| Attachment Type | Threaded, Keyed Hole |

| Brands | Scotch-Brite™ |

| Center Hole Thread Size | 5/8"-11 |

| Density | 7 |

| Density Rating | Hard |

| Equipment - Machines | Inline Sanders |

| Grade | Medium, Coarse |

| Industries | Metalworking |

| Maximum Speed | 3500 rpm |

| Product Color | Brown, Gold |

| Product Form | Flap Brush, Brush |

| Sub Applications | Blending |

| Sub Industries | Metal Fabrication |

| Overall Diameter (Imperial) | 4.5 in |

| Overall Diameter (Metric) | 114.3 mm |

| Overall Width (Imperial) | 4 in |

| Overall Width (Metric) | 101.6 mm |

Resources

Safety Data Sheets

Document Number: MSDS_2973998_US_EN

(PDF)

Reviews

Large Volume Order

Thank You!

Your form was submitted successfully.

Our Apologies...

An error has occurred while submitting. Please try again later...

For industrial/occupational use only. Not for consumer sale or use.

3M industrial and occupational products are intended, labeled, and packaged for sale to trained industrial and occupational customers for workplace use. Unless specifically stated otherwise on the applicable product packaging or literature, these products are not intended, labeled, or packaged for sale to or use by consumers (e.g., for home, personal, primary or secondary school, recreational/sporting, or other uses not described in the applicable product packaging or literature), and must be selected and used in compliance with applicable health and safety regulations and standards (e.g., U.S. OSHA, ANSI), as well as all product literature, user instructions, warnings, and other limitations, and the user must take any action required under any recall, field action, or other product use notice. Misuse of 3M industrial and occupational products may result in injury, sickness, death, or property damage. For help with product selection and use, consult your on-site safety professional, industrial hygienist, or other subject matter expert.

Scotch-Brite™ Match and Finish High Strength Flap Brush

Scotch-Brite™ Match and Finish High Strength Flap Brush Scotch-Brite™ Roloc™ High Strength Disc

Scotch-Brite™ Roloc™ High Strength Disc Scotch-Brite™ High Strength Disc

Scotch-Brite™ High Strength Disc Scotch-Brite™ High Strength Flap Brush

Scotch-Brite™ High Strength Flap Brush